Decarbonization is one of the keys to our sustainable society and drastic CO2 emission reduction by expanding the use of heat pumps is expected, accounting for 14% of Japan’s ambitious CO2 reduction target in 2050, according to Heat Pump & Thermal Storage Technology Center of Japan (HPTCJ)’s latest analysis (see the previous report).

The potential CO2 emission reduction by heat pumps in the industrial heating sector (33.54 Mt-CO2/yr) accounts for the largest part and that of the commercial hot water supply sector (6.01 Mt-CO2/yr) accounts for a considerable part of total contribution of heat pumps when compared to BAU scenario *1, which means heat pumps should play an important role and efforts to expand the use of heat pumps in these sectors will be needed to attain this sizeable CO2 emission reduction.

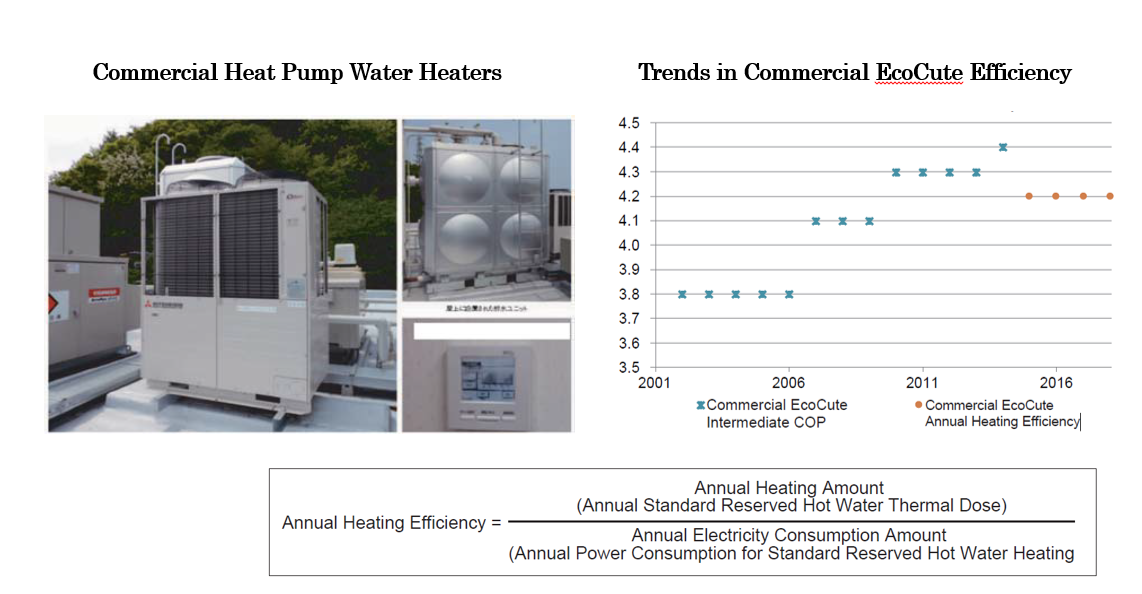

- Commercial Heat Pump Water Heaters

Heat pump water heaters are an efficient way to produce hot water. Only about 1/3 (this depends on conditions like heat source temperature) of heat output is required as energy input because heat pumps can utilize not high-temperature but abundant renewable heat such as ambient, underground or waste heat. Its efficiency has been improved and the Annual Heating Efficiency reached 4.2.

Heat pump water heaters are gaining popularity and being used to replace conventional combustion boilers. Cumulative shipments of residential “EcoCute” heat pump water heaters with natural CO2 refrigerant surpassed 7 million units in Japan at the end of June 2020. More and more commercial “EcoCute” and other types of heat pump water heaters are also being installed.

A wide range of heat pump water heaters are available, varying from compact models for residential use to larger commercial models for pools and spas. In terms of operating temperature, some models can produce hot water of 90˚C, even from an ambient heat source of -25˚C in cold climate. Hybrid hot water supply systems which combine heat pumps with combustion boilers are also possible.

Thanks to its higher efficiency compared to combustion boilers, energy consumption and CO2 emission reduction can be achieved by using heat pumps. The use of hot water stored in tanks allows the system to suspend operations during peak hours and operate during off-peak hours utilizing less expensive nighttime rate and thus level the electric loads and reduce running costs.

Heat pumps are equipped with either natural refrigerant (CO2) or HFC refrigerant;

- natural refrigerant (CO2)

- Environmentally considerate refrigerant with ODP (Ozone Depletion Potential) of 0 and GWP (Global Warming Potential) of 1

- Maximum water temperature of 90 ˚C makes storage tanks compact and meets various requirement for high temperature such as dish washers.

- Many models raise the temperature from feed-water temperature to high temperature with a single pass. (some models support circulated heating as well)

- HFC refrigerant

- Two types of heating systems exist; circulated heating with constant temperature difference (about 5˚C) and single pass temperature raising.

- The maximum temperature is 70˚C for many models, because it significantly reduces the efficiency to raise temperature up to 90˚C, although technically possible.

- Products can be delivered with a high degree of reliability at relatively low cost since many parts are in common with other heat pump equipment, such as air conditioners,

Tanks can be divided into 2 types;

- Sealed tanks

- Made of stainless steel. Hot water can be supplied using service water pressure by, since it is possible to connect the tank to the service water system. Hot water supply to lower floors is restricted since negative pressure can cause damage,

- Open tanks

- Many are panel tanks built on site, made of using stainless steel or FRP. The internal pressure of a tank is atmospheric and a pump for supplying the hot water is required separately, however, it supports an instantaneous supply of large quantities of hot water or the supply of hot water to the lower floors with piping over a long distance.

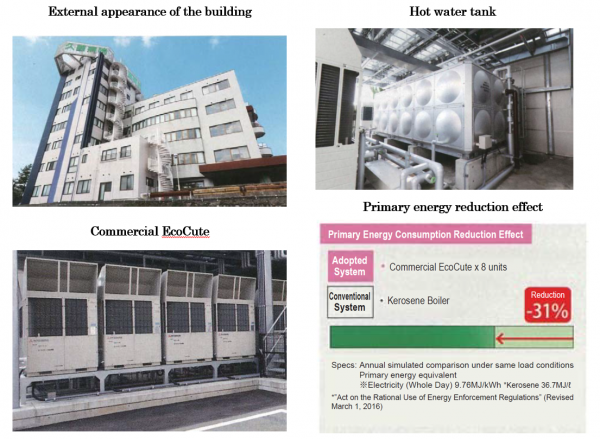

Hospital

A hospital located in Ishikawa Prefecture (11,665 m2, 199 beds), opened in 1970, installed commercial EcoCute heat pump water heaters of 240 kW (30kW * 8 units) and 32 m3 tank to replace aged kerosene boilers with the intention of running cost reduction. As a result of replacement, primary energy consumption has been reduced by about 31%.

-

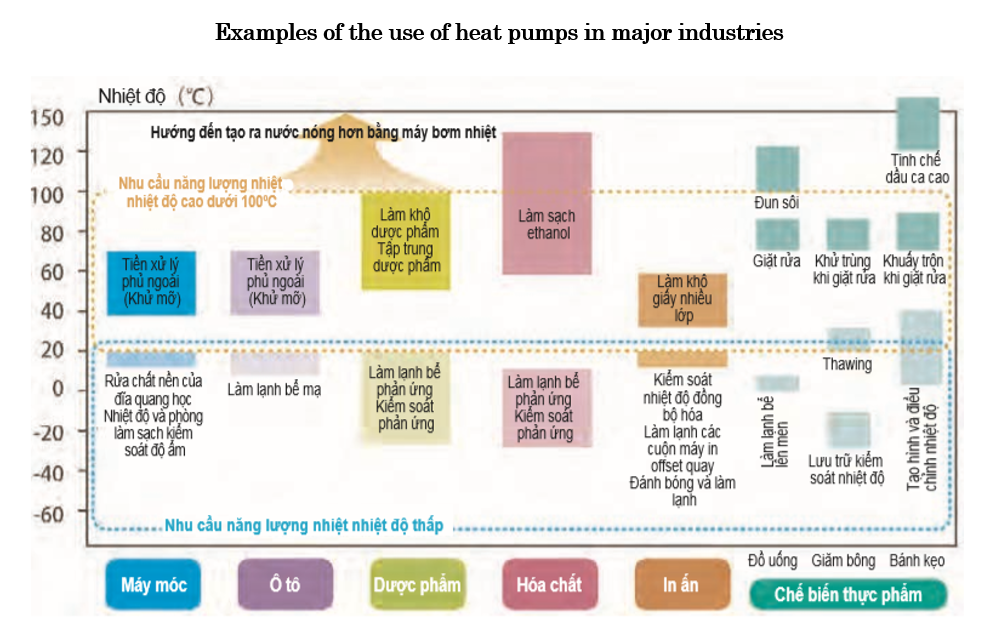

- Industrial Heat Pumps

Industrial heat pumps are defined as one of the important energy-saving measures in Japan’s Long-term Energy Supply and Demand Outlook, accounting for 8% of total energy reduction of the industrial sector in Japan. As mentioned above, we see the largest CO2 emission reduction potential in the industrial heating sector.

High temperature heat pumps which can supply hot water of up to 120˚C have been developed and this allows decentralized heat pump systems to substitute conventional centralized boiler systems. Significant energy saving can be achieved not only by the energy-efficient nature of heat pumps but also by reducing heat loss from piping and drain by decentralization.

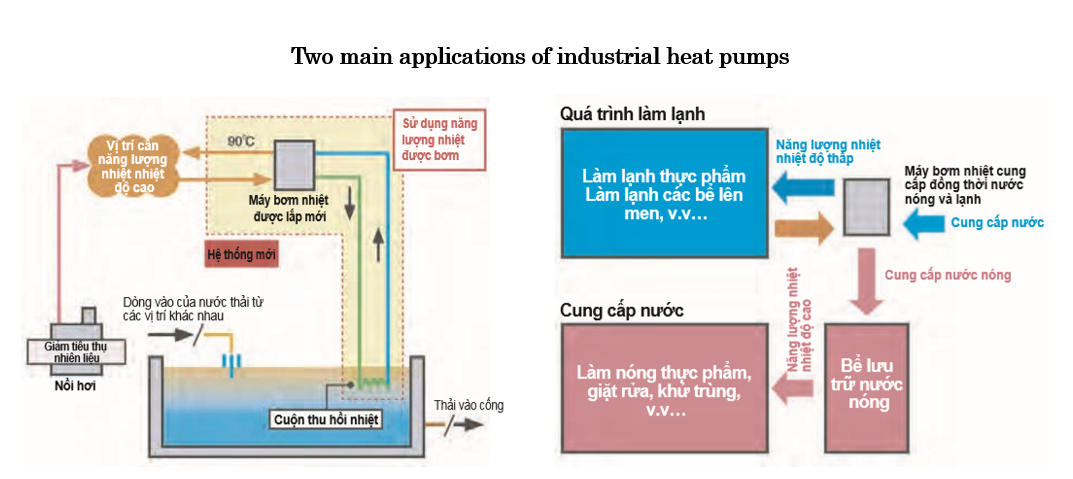

There are two main applications of industrial heat pumps.

- Waste heat recovery heat pumps [Use of wasted heat]

- Unusable waste heat at several tens of degrees can be used as an effective heat source.

- In case there is time lag between waste heat generation and heat demand, it is possible to use waste heat by installing hot water tanks.

- Heat pumps for simultaneous supply of hot and cold water [streamlining of cooling and heating]

- The heat pump technology can be used to simultaneously supply hot and cold thermal energy.

- In case there are both heating and cooling demand (e.g. food processing plants), simultaneous supply of hot and cold water enables significant energy reduction with twofold energy efficiency compared to ordinary one-side heat pump application.

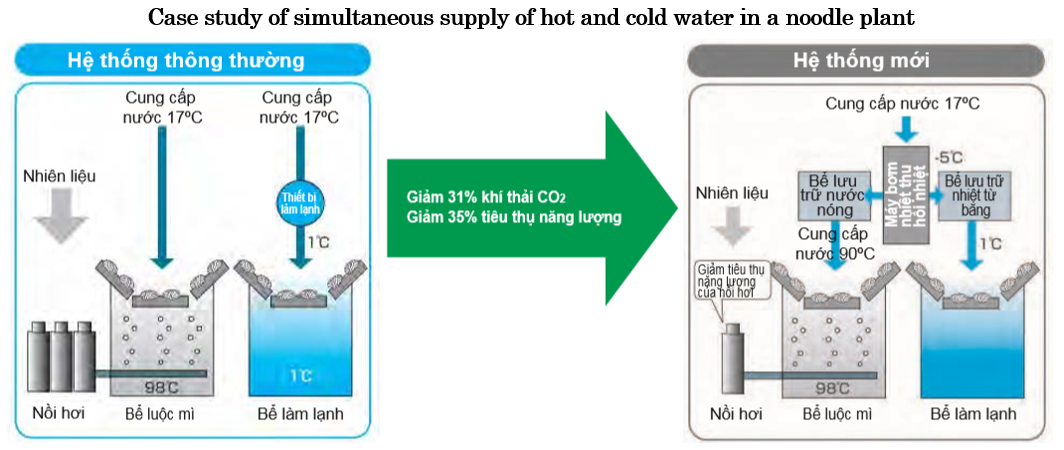

Noodle plant

Noodle needs to be boiled and then cooled in separate tanks. The new heat pump system installed in this plant simultaneously supplies hot and cold energy which used to be supplied separately by boilers and chillers until then.

The hot water stored in a hot water storage tank (90˚C) is supplied to the noodle boiling tank and further heated by boilers (98˚C), reducing the fuel consumption by boilers. Cold energy (-5˚C) is stored in ice thermal storage tanks and used to produce cold water (1˚C) for the cooling tank without the need for additional chillers.

As a result of this renovation, CO2 emissions have been reduced by 31%.

A new “Subsidy for promoting high-efficiency heat pumps installation in commercial and industrial sectors” is being planned in Japan in the FY2020 supplementary budgets bill announced on 15 Dec 2020, where heat pumps of certain efficiency which contribute to energy saving in factories, warm bath and other facilities will be subsidized. This will be Japan’s first-ever subsidy dedicated to industrial HPs and such governmental assistance will also be expected.

As we’ve discussed, expanding the use of heat pumps, especially commercial heat pump water heaters and industrial heat pumps, will be the key to decarbonization. A lot of technology and products are already available and we, HPTCJ will do our best for further dissemination of these heat pumps.

Other definition:

* 1 BAU refers to natural cases (Business As Usual) without any special measures. Here, HPTCJ uses fixed cases where the stock share and flow efficiency of each heat pump in FY2018 is assumed to be constant in the future. The final energy consumption reduction effect is based on the idea that the difference from BAU in the Long-term Energy Supply and Demand Outlook is the reduction amount. Also, regarding the greenhouse gas reduction effect, the reduction amount is based on the difference compared to the CO2 emissions in FY2013 in Japan’s INDC. In both cases, as the base year and the future outlook for macro frames are different, and simple comparisons are not possible, this is for reference purposes only.

Source: HTPCJ.